Liebherr D9812. Awarding ceremony

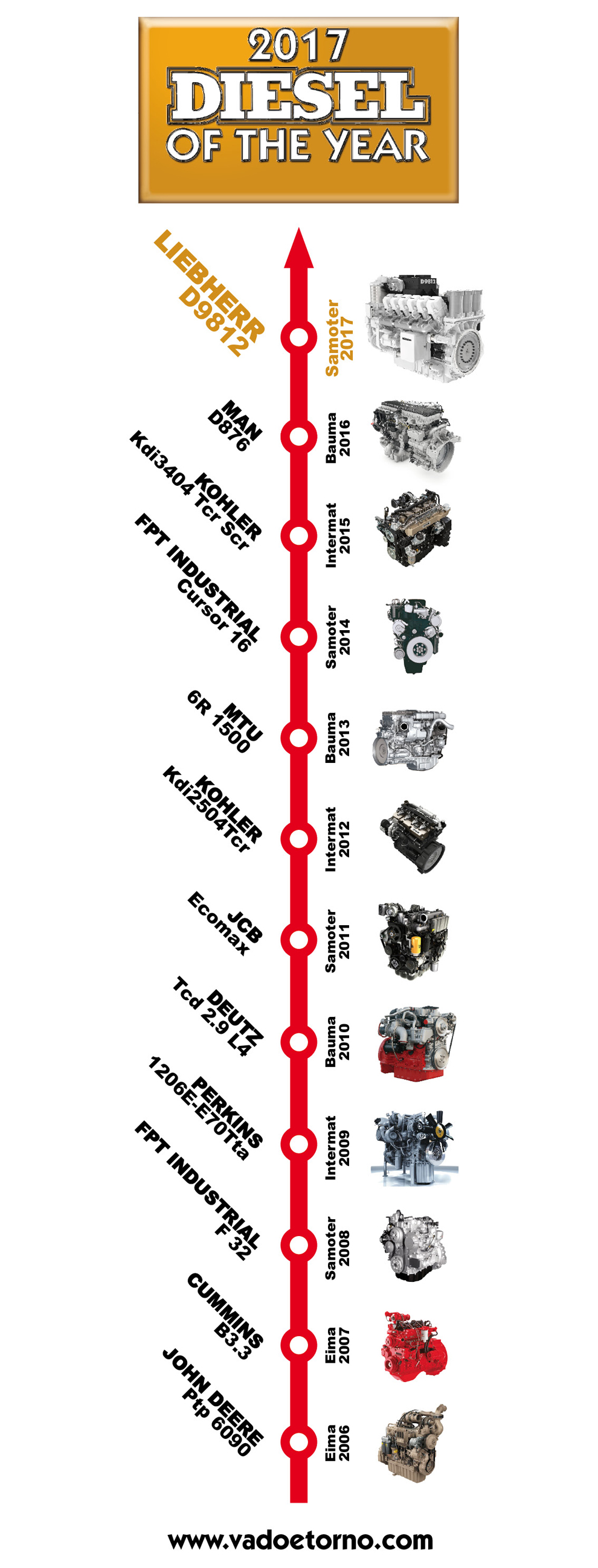

Liebherr D9812. A BIG ceremony Samoter Verona, Italy, February 23. Liebherr receives the plate of the Diesel of the year 2017. The prize recognizes the innovation spirit of D9812, a 62-liter diesel engine with the maximum power output of 2,700 kW and 15,000 Nm. An optimised power density, the courage to invest in a niche […]

Liebherr D9812. A BIG ceremony

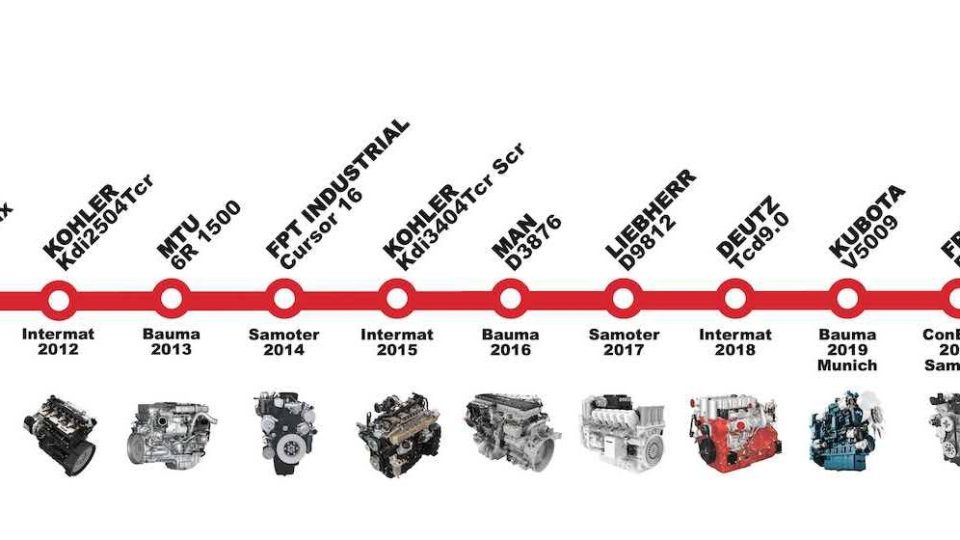

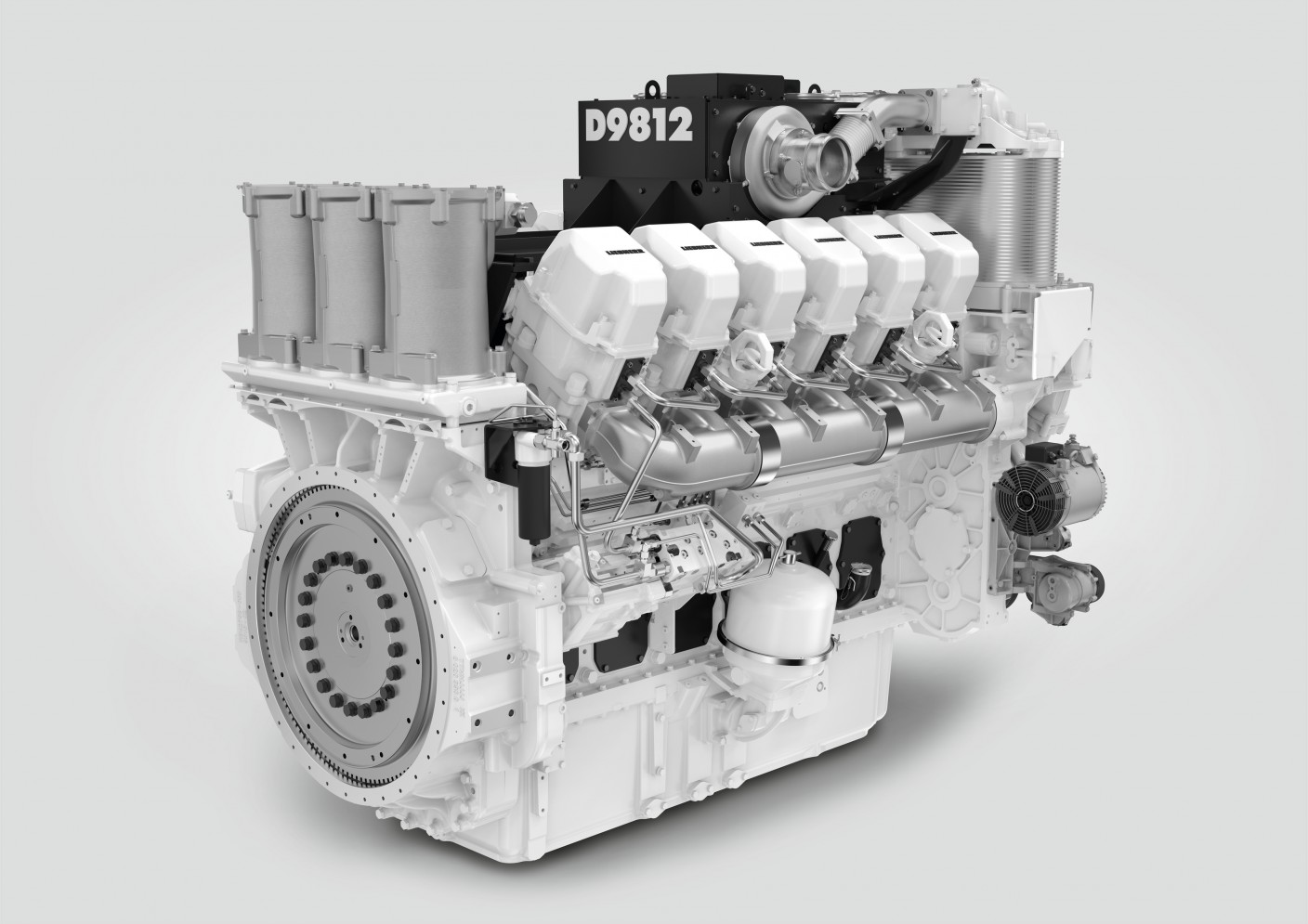

Samoter Verona, Italy, February 23. Liebherr receives the plate of the Diesel of the year 2017. The prize recognizes the innovation spirit of D9812, a 62-liter diesel engine with the maximum power output of 2,700 kW and 15,000 Nm. An optimised power density, the courage to invest in a niche such as the over 20-liters displacement engines, the peculiar application for mining, the 2,200 bar common rail system by Liebherr are some of the reasons for the prize. Step by step Liebherr is on the way to be a protagonist in the industrial engines and components market. Mr. Diethard Plohberger, Managing Director Liebherr Components Colmar SAS, thanks Diesel magazine for the award and provides insight into the specific characteristics of the new engine:

«As you may already know, Liebherr has a long tradition in the manufacturing of engines and drive technology, which goes back for nearly 30 years. At Liebherr site in Bulle situated in the Swiss canton of Fribourg, the first diesel engines went into production in 1985, and since then some 130,000 engines of different models series and emission standards have been built. Today, with the launch of the new D98XX engine series, we are including the fifth series into our diesel portfolio. Once all the cylinder configurations of the D98XX series are available, the Liebherr diesel engine portfolio will cover the power range from 200 kW to 4,500 kW. This new diesel engine series has been designed, developed and tested at our new facility in Colmar, France, where the engines are also produced. With the maximum power output of up to 2,700 kW, and 2,013 kW in mining application, the 12-cylinder, V-configuration D9812 diesel engine is the first model of the new D98XX series. All variants of the D98XX series feature, among other parts, ECUs and common rail fuel injection systems designed and manufactured by Liebherr.

D98XX: mining engines

The engines of the D98XX series have been designed as mining engines and as such they feature specific characteristics and important components for use in a mining excavator or a truck. These are, for example, an improved oil and cooling system, special wiring harness and connectors, as well as other

small but important details. The engine is designed for operation under the most demanding environmental conditions, such as heat, dirt, humidity, bad fuel and oil qualities, high altitudes, arctic conditions and others. The new engine family D98XX deals with these challenges by means of a rugged and clear design. This feature and the high-performance turbo chargers make the engine also attractive for other segments as, for example, power generation, oil & gas or railway applications. [fusion_builder_container hundred_percent=”yes” overflow=”visible”][fusion_builder_row][fusion_builder_column type=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none”][…] The D9812 engine is the first cylinder variant available. A V16 and also a V20 are currently under development. We are looking forward to present them to you and hope they will arise as much interest as the award winner, the D9812».

Thanks, Mr Plohberger.

[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]